Ceramic Capacitor Uses Tech Talk The Powerful Innovation Transforming Modern Electronics

Ceramic capacitor uses tech talk covers one of the most crucial aspects of modern electronics. From smartphones to electric vehicles, ceramic capacitors play an essential role in keeping circuits stable and efficient. While they may appear as tiny, unassuming components, understanding ceramic capacitor uses tech talk reveals the sophistication behind their design, construction, and applications.

Understanding Ceramic Capacitors

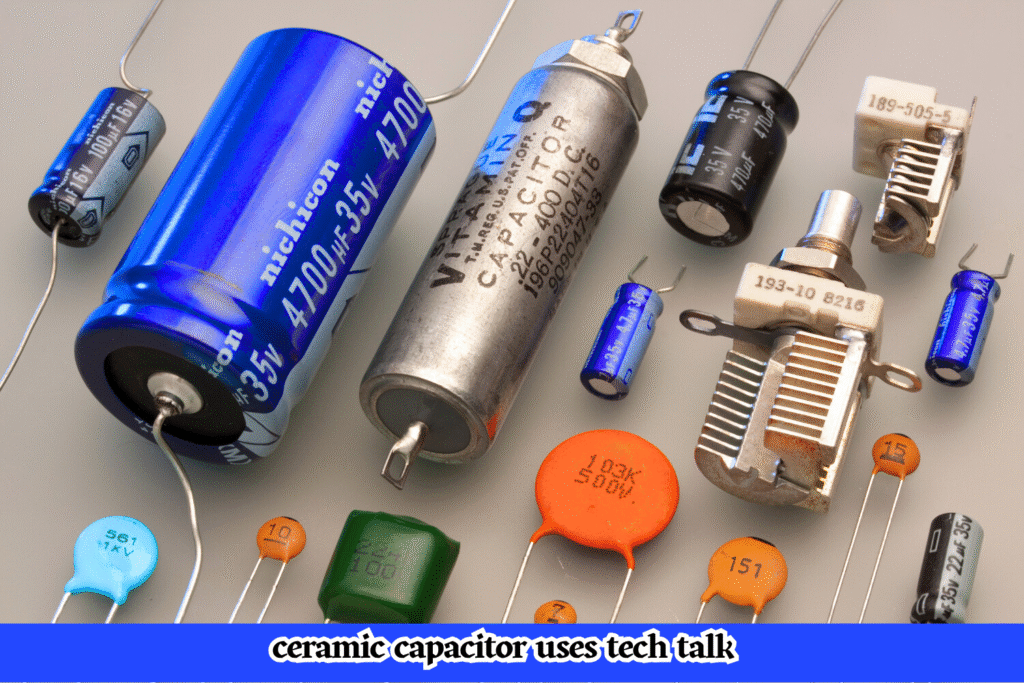

When discussing ceramic capacitor uses tech talk, it’s important to first understand what a ceramic capacitor is. A ceramic capacitor is a passive electronic component that stores and releases energy using a ceramic material as the dielectric. This dielectric material separates conductive plates, enabling the storage of electrical charge. Unlike electrolytic capacitors, ceramic capacitors are non-polarized, which makes them flexible in circuit design.

Modern applications of ceramic capacitor uses tech talk often involve Multi-Layer Ceramic Capacitors (MLCCs). These consist of multiple thin layers of ceramic dielectric alternated with metal electrodes. The multilayer structure dramatically increases capacitance while maintaining a compact footprint. In practical electronics, this small size allows designers to integrate capacitors close to critical ICs for noise reduction and power stability.

Construction and Classification

From a technical perspective, understanding ceramic capacitor uses tech talk also involves knowing how these capacitors are built. The electrodes in a ceramic capacitor are usually made of nickel or silver-palladium, and the ceramic layers are engineered for specific electrical properties. The combination of ceramic material and metal layers defines performance characteristics such as stability, capacitance, and tolerance.

In ceramic capacitor uses tech talk, capacitors are categorized by dielectric classes. Class I dielectrics like C0G (NP0) provide highly stable capacitance, ideal for precision timing and oscillator circuits. Class II dielectrics, such as X7R and X5R, offer higher capacitance for smaller packages but can vary with temperature, voltage, and aging. Selecting the right class is a critical part of understanding ceramic capacitor uses tech talk in both professional and hobbyist designs.

Ceramic Capacitor Bio Table

| Attribute | Details |

|---|---|

| Component Name | Ceramic Capacitor |

| Type | Fixed-value, non-polarized capacitor |

| Dielectric Material | Ceramic (various classes: Class I – C0G/NP0, Class II – X7R/X5R) |

| Common Form | Multi-layer ceramic capacitor (MLCC), disc type |

| Applications | Decoupling, filtering, timing, coupling, AC blocking, high-voltage systems |

| Operating Voltage | Typically from a few volts to several kilovolts depending on type |

| Capacitance Range | Picofarads (pF) to tens of microfarads (µF) |

| Temperature Stability | High (Class I), Moderate (Class II) |

| Advantages | Compact size, high-frequency performance, long lifespan, non-polarized |

| Limitations | Capacitance can vary with voltage, temperature, and aging; microphonic effect possible |

| Industries Used In | Consumer electronics, automotive, telecommunications, industrial equipment |

| Lifespan | Typically 10+ years under normal conditions |

| Package Sizes | 01005, 0201, 0402, 0603, 0805, 1206, etc. |

How Ceramic Capacitors Work

To explore ceramic capacitor uses tech talk, one must consider their electrical behavior. Ceramic capacitors store energy when voltage is applied and release it as needed, effectively smoothing power supply fluctuations or allowing AC signals to pass while blocking DC. This quick response to voltage changes makes them ideal for high-frequency applications.

In practical ceramic capacitor uses tech talk, you’ll find these capacitors directly placed next to microprocessors or other high-speed ICs on PCBs. They absorb voltage spikes, filter out noise, and provide a stable environment for digital and analog signals alike. This simple function is foundational to why ceramic capacitors are ubiquitous in electronics.

Everyday and Industrial Applications

Ceramic capacitor uses tech talk are incredibly broad, spanning from everyday gadgets to industrial machinery. Understanding these uses in detail illustrates their importance.

Decoupling and Bypassing: In virtually every circuit, ceramic capacitors provide decoupling, ensuring stable voltage for sensitive components. Engineers frequently use ceramic capacitor uses tech talk to explain why MLCCs are placed directly across IC power pins to suppress high-frequency noise.

Signal Filtering: Another key aspect of ceramic capacitor uses tech talk involves filtering unwanted noise in signals. Whether in audio amplifiers or RF communication circuits, these capacitors maintain signal integrity by removing high-frequency disturbances.

Timing and Oscillation: For precision circuits, ceramic capacitor uses tech talk highlights the importance of stable Class I capacitors like C0G, which allow oscillators and timing circuits to operate without drift.

Coupling and Blocking: In analog and mixed-signal designs, ceramic capacitor uses tech talk often points out their ability to pass AC signals while blocking DC offsets. Their non-polar nature makes them ideal for coupling applications.

Automotive and High-Voltage Applications: In electric vehicles and industrial equipment, ceramic capacitor uses tech talk includes their role in smoothing power rails, reducing EMI, and handling voltage spikes. Disc-type capacitors, designed for high-voltage applications, are widely used in inverter and power systems.

Benefits of Ceramic Capacitors

The benefits are central to ceramic capacitor uses tech talk, explaining why these capacitors are so widely adopted.

Compact Size: MLCCs provide high capacitance in a very small footprint. In ceramic capacitor uses tech talk, this allows engineers to integrate multiple capacitors close to high-speed ICs for efficient noise suppression.

High-Frequency Performance: One key insight in ceramic capacitor uses tech talk is their low parasitic resistance and inductance, which make them ideal for GHz-range signals and decoupling power supplies.

Durability: Another aspect of ceramic capacitor uses tech talk is reliability. With no liquid electrolyte, ceramic capacitors handle vibration, shock, and extreme temperatures better than many alternatives.

Non-Polarized and Versatile: In ceramic capacitor uses tech talk, the non-polarized nature simplifies PCB layout and allows capacitors to be used in a wide range of applications.

Cost-Effective: Their mass production and mature manufacturing process make ceramic capacitors economical, a crucial factor often discussed in ceramic capacitor uses tech talk sessions.

Challenges and Considerations

Even in ceramic capacitor uses tech talk, limitations are always highlighted.

Capacitance Drop under DC Bias: High-capacitance Class II capacitors can lose a significant portion of their nominal value under normal operating voltage. Designers must account for this behavior when discussing ceramic capacitor uses tech talk.

Temperature and Aging: In ceramic capacitor uses tech talk, engineers emphasize the effects of temperature swings and aging, which can slightly alter capacitance over time.

Microphonic Effect: Certain ceramic capacitors may generate electrical noise due to mechanical vibration. Understanding this in ceramic capacitor uses tech talk is crucial for high-fidelity audio or precision analog systems.

High-Capacitance Limitations: While perfect for small, high-frequency applications, ceramic capacitors have limitations for extremely high-capacitance or ultra-high-voltage applications, a key point in ceramic capacitor uses tech talk.

Modern Developments

Ceramic capacitor uses tech talk is not static; the field continues to evolve. Miniaturization, automotive-grade reliability, and high-frequency optimization are recent trends. MLCCs now fit into 0201 or even 01005 packages while maintaining stability.

High-Density Capacitors: In ceramic capacitor uses tech talk, these advancements allow more capacitance per volume, enabling thinner devices without compromising electrical performance.

5G and High-Speed Electronics: As signal frequencies increase, engineers often discuss ceramic capacitor uses tech talk to highlight how low-ESL capacitors maintain signal integrity in cutting-edge devices.

Automotive and Industrial Applications: Ceramic capacitor uses tech talk also covers the importance of AEC-Q certified capacitors capable of surviving extreme temperatures, vibration, and high voltages in EVs and industrial machinery.

Bias and Reliability Modelling: Modern datasheets now include detailed bias-capacitance and aging curves, a frequent topic in ceramic capacitor uses tech talk, helping engineers accurately predict performance over the capacitor’s lifetime.

Practical Tips for Designers

In professional ceramic capacitor uses tech talk, proper selection and placement are key. Choose the right dielectric based on stability requirements — Class I for precision, Class II for general-purpose filtering. Always check voltage derating and bias curves, and position capacitors close to critical ICs to minimize parasitic effects.

In ceramic capacitor uses tech talk, small package sizes must be carefully considered to ensure capacitance under real-world operating conditions. For audio and precision analog applications, microphonics must be accounted for by selecting stable dielectrics or mechanically damping the board.

Conclusion

Understanding ceramic capacitor uses tech talk reveals that these tiny components are far more than passive placeholders. They provide stability, reduce noise, and maintain signal integrity across an incredible range of applications. From everyday electronics to high-speed communication systems and automotive applications, ceramic capacitor uses tech talk underscores their critical role.

Whether you’re a hobbyist, student, or professional engineer, diving into ceramic capacitor uses tech talk equips you with the knowledge to make informed design decisions. Their continued evolution — smaller, more reliable, higher-performing — ensures that ceramic capacitors remain a cornerstone of modern electronics for years to come.

FAQs

1. What is a ceramic capacitor used for?

Ceramic capacitors are used to store and release electrical energy, filter signals, and stabilize voltage in electronic circuits.

2. How does a ceramic capacitor work?

It works by storing charge between two conductive plates separated by a ceramic dielectric, helping smooth voltage and reduce noise.

3. What are the main types of ceramic capacitors?

The two main types are Class I (stable, precise) and Class II (high capacitance, compact but less stable).

4. Why are ceramic capacitors important in modern electronics?

They are compact, reliable, and essential for power filtering, signal coupling, and noise suppression in all electronic devices.

5. Can ceramic capacitors fail or wear out?

Yes, though rare — extreme heat, mechanical stress, or overvoltage can cause them to crack or lose capacitance over time.